These determine the depth of the cut by the cutters. These are the cutters in the chain that cut the wood and come in 2 styles: right-hand and left-hand cutters.Īlso called “rakers”, these are metal protrusions that are at the front of the cutter teeth. Nonetheless, all chainsaw chains have the same basic parts and you will know them better below.Ĭhainsaw Chain and Its Parts Chainsaw Pitch – This is the distance between the three rivets on the chain and measured in inches.ĭescribes how thick the drive link is and also measured in inches.

#Chainsaw depth gauge full

A dull chainsaw can even be dangerous to use due to kickbacks.Ĭhainsaw chains come in 3 different basic configurations – the full chisel, the semi-chisel and the chipper chain.

#Chainsaw depth gauge how to

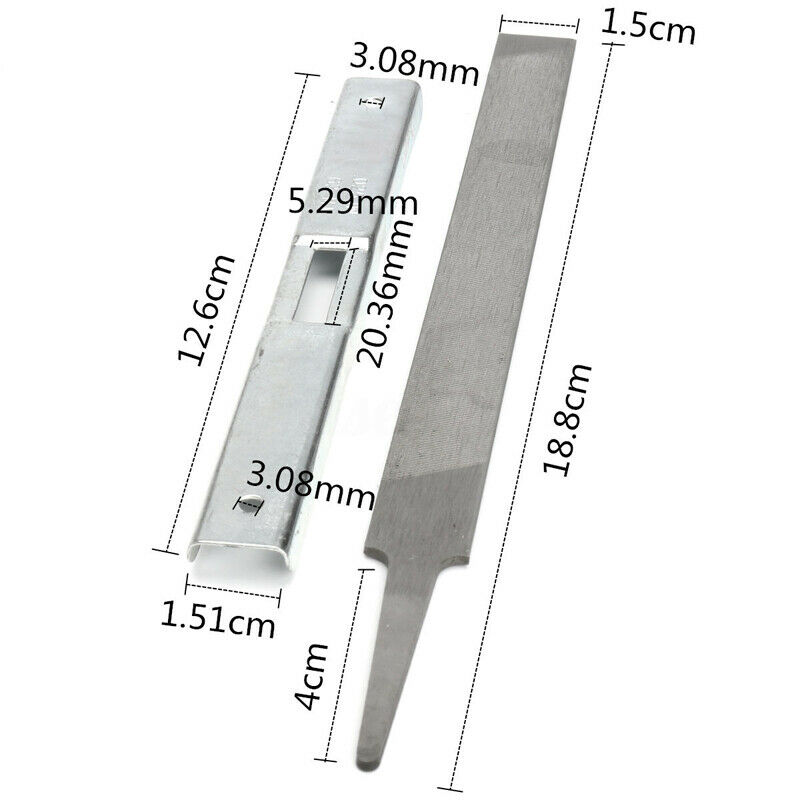

Even with a heavy-duty chainsaw, if you don’t know how to sharpen the teeth of the chain and you’re using the wrong file size, your chainsaw won’t work well. How to find the best chain sharpener products in the market is important because the performance of your chainsaw also depends on the sharpness of its chain. Some of them are better used for logging, while some types are best for tree surgery and some for firewood cutting. Chainsaw chains come in different types and lengths. You’ll also find it easier to line up the file guide and maintain a more consistent stroke when working from the inside of the tooth.Anyone who uses a chainsaw knows that regular chain sharpening is a must and various chainsaw file sizes are appropriate for every sharpening process. Filing from the outside to the inside will wear out the file in short order since the outside of the tooth is chrome-plated and harder than the file material. Filing backwardsĪlways file from the inside of the tooth to the outside, and don’t drag your file backwards. If sharpening in the field, consider using a stump vice, or brace the tip of the bar on a log and lock the chain brake. Keep even pressure with each stroke, and keep the number of strokes consistent for each tooth. The best way to brace the chainsaw when sharpening is to place the bar in a bench vice. If you’re using a filing tool where the file is in a fixed position, remember to regularly rotate the file for even wear. If adding pressure causes the file to skate, chances are your file is worn out. As you push and add pressure to the file you should feel it grab. Using a dull fileĬhainsaw chain is extremely hard and requires a sharp file. The result is that the saw is overworked and bogs down it also makes the saw prone to kickback. Over-filing the depth gaugeĬonversely, some people over-file the depth gauge so that the saw takes a bigger chip. Failing to file the depth gauge and only filing the cutter teeth will result in smaller and smaller chips with each subsequent sharpening. Because the top plate of the cutter tooth is angled back slightly, it is essential that the depth gauge be lowered as the cutter teeth are filed back. The depth gauge (rakers) on a chainsaw control how deep the cutter teeth penetrate. Filing the cutters, but not the depth gauge 325 pitch chain, you should use a 3/16-inch file for 3/8-inch pitch, use a 5/32-inch file. Using a file that’s too small in diameter will prevent the top edge of the cutter from being sharpened, while a file that’s too large will remove the hook of the tooth, which is essential for efficient cutting. Using the proper size of file allows the filer to adhere to the 80 percent/20 percent rule, by which 80 percent of the file is inside the cutter, and 20 percent is above the cutter, creating a sharp, crescent-shaped hook on the end of the cutter tooth.

It’s essential to choose a round file that’s the correct size for the pitch of the chain being sharpened. Here’s a look at some common chainsaw sharpening myths and mistakes: Using the wrong-size file (specifically for round-tooth chain)

To compensate for a dull or damaged chain, sawyers often use the felling dogs to create more leverage, or use a comical back-and-forth sawing motion (treating a running chainsaw as if it were a bow saw), which is both unsafe and ineffective. Given those obvious benefits, it still surprises me to see people struggling with dull saws.

Maintaining a sharp chainsaw chain not only makes for faster cutting, it also reduces wear and tear on the saw and the sawyer. The sharpening tool pictured here also includes guides that make for a more consistent filing job. Some sharpening devices combine both the round tooth file and flat depth gauge file.

0 kommentar(er)

0 kommentar(er)